Short-Run & Mass Production Mold Making Services

Whatever you need prototype molds for the short-run production, or mass production molds for millions shots, we can handle them for you smoothly.

Our Advantages of Mold

Making Services

1. Fast DFM reports

Although we check your design feasibility when providing a quote, we can provide a fast and thorough DFM (design for manufacturability) report before production begins. In the DFM report, we’ll identify any errors or issues that might cause a manufacturing problem down the line.

2. Wide range of molds

We offer several different types of molds, which means you can avoid splitting your projects; just send everything to us to ensure your project runs smoothly.

3. Fast Turnaround

Our large facility and machining capabilities allow us to build molds quickly, whatever the application or material, which means you can get your moldings completed faster.

4. Molding Capabilities

We can ship your molds to you directly, but we can also handle injection molding and other production services to deliver you prototypes and final parts using those molds.

Mold Making Processes

Mold making is a complex process that requires a high level of skill and experience.

Although each case is different, a typical order for a set of molds may go something like this:

1. DFM

As soon as the customer confirms the order of molds, we will start to do an initial analysis of the parts to get an idea of the part line, gate positions, etc.

2. Mold design and mold flow analysis

The second step involves the use of predictive modeling software which allows us to see how the molten material will behave when it enters the mold, allowing for further improvements to the design.

3. CNC machining and EDM

We make the first molds using high-quality machining equipment, with the plastic, steel, aluminum, etc. chosen by the customer.

4. T1 sample

With the newly made molds, we make a T1 sample to have a clear vision of how the customer’s final molded parts will turn out.

5. Improvement if necessary

Based on our analysis of the T1 sample, we review the mold design and make any adjustments needed.

6. Commence production and shipping

We manufacture the molds in accordance with the final specifications before shipping them to the customer.

Types of Molds We are Offering

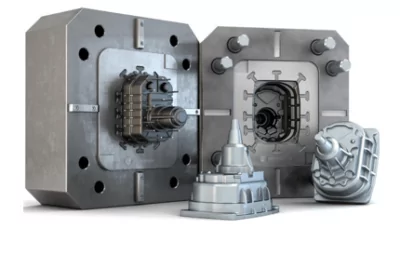

Plastic Injection Mold

Plastic injection molds are aluminum or steel molds used to make parts from a wide range of plastics, including nylons, acrylics, elastomers and reinforced materials like glass-filled polyamide. Custom plastic molds can last between 100,000 and 1,000,000 shots.

Metal Injection Mold

Metal injection molding (MIM) is a form of injection molding where a metal and binder mix is used as feedstock. A metal injection mold is usually made from tool steel to withstand the metal injection, but we can also use aluminum.

Die Casting Mold

Unlike many prototyping specialists, we can provide metal casting molds (and a low-volume casting service through our partners). These molds — typically made from hardened steel — can be used to make parts from aluminum, zinc, magnesium and other non-ferrous metals.

Investment Casting Mold

We can make low-cost investment casting molds by 3D printing a wax pattern and surrounding it with ceramic. The ceramic molds can then be used to make metal cast parts from metals like aluminum, zinc, magnesium, stainless steel and more.

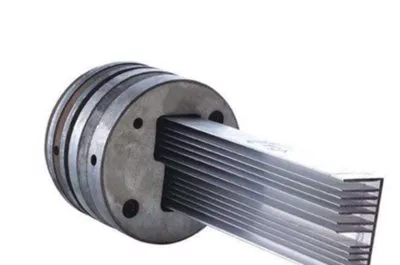

Extrusion Mold

Our metal die molds can be used for aluminum extrusions of alloys like 6061 and 6063. We also make molds for plastic extrusions of materials like polystyrene, nylon, polypropylene and polythene.

Sheet Metal Mold

Our experience making sheet metal molds for stamping and bending allows us to create sheet metal prototypes.

Mold Making FAQ's

What Is Mold Making And When Do You Need It?

Molds are normally created to duplicate plastic and metal parts. After testing the prototypes and the market, it is the most cost-efficient way to launch your products at scale.

Should I Choose A Locally Produced Mold Or An Exported Mold?

Generally speaking, making plastic or metal molds (and moldings) is cheaper in China than other countries. But shipping costs should also be considered: you will need to use air freight if you have a tight schedule; sea freight is much cheaper, but will usually take 40 days or more.

How Long Does A Mold Last?

A well-made, fully harden steel mold may be used for up to a million shots or injections, depending on the mold shape and injection material. Aluminum molds are less durable, which is good for short-run production with tight schedule.

Can Molds Be Any Shape?

Molding designs should avoid sharp corners, inconsistent wall thicknesses, and other features that restrict material flow.

When Do I Need Full Automatic Mold?

Whatever you decide to use, in the end, what is the best cost-efficient way to get your parts done in the required quality is the key.

Put your parts

into production today

All information and uploads are secure and confidential.