Robotics & Automation

Prototyping

Get high-quality manufacturing services for your custom aerospace prototypes and production parts. Launch products faster, reduce risks, and streamline production processes with on-demand production at competitive prices.

- Production-grade products

- ISO 9001:2015 certified

- 24/7 engineering support

Robotics & Automation Manufacturing Possibilities

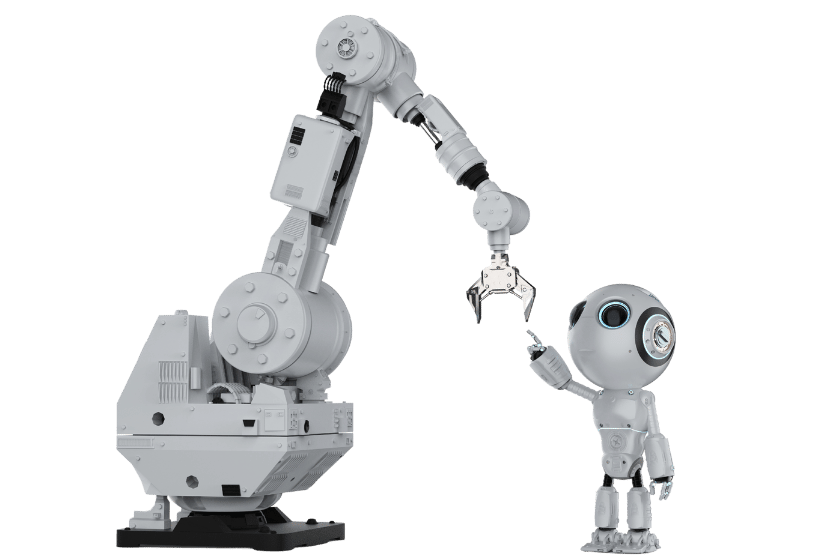

In the robotics industry, most robotic systems typically require a rugged, sturdy frame that allows the system to perform a range of useful mechanical motions, such as swiveling, extending, or carrying out a specific task with its end effector. At 3ERP, we can use our range of manufacturing processes and reliable materials to make high-quality metal parts like frames, shoulder joints, and gears.

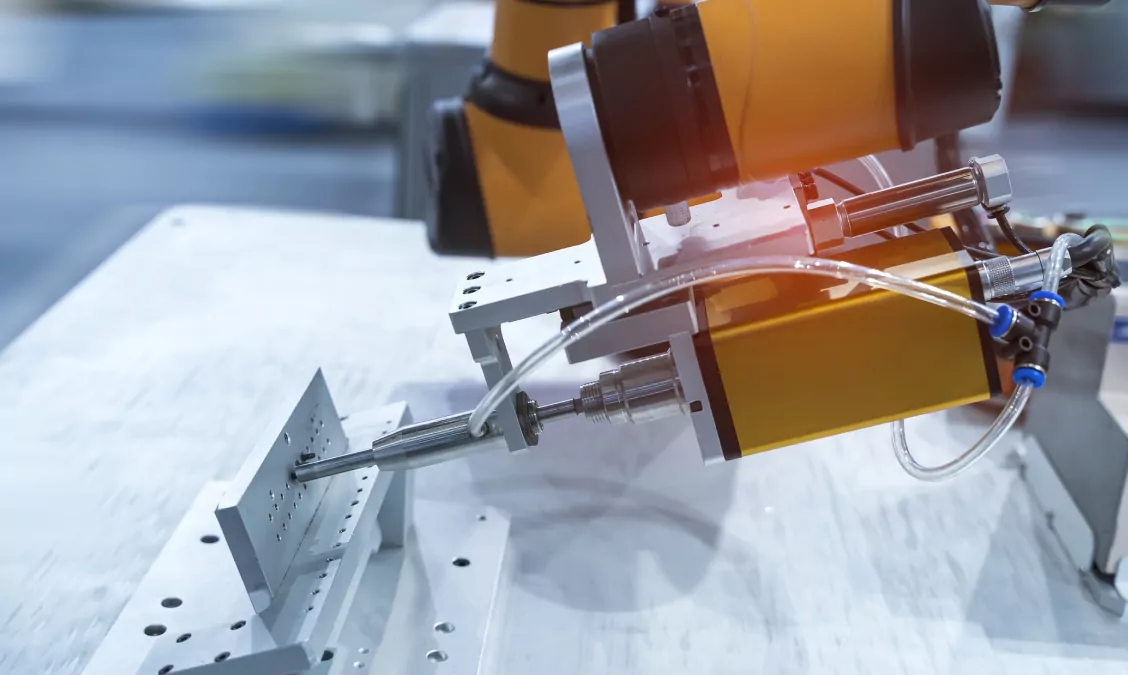

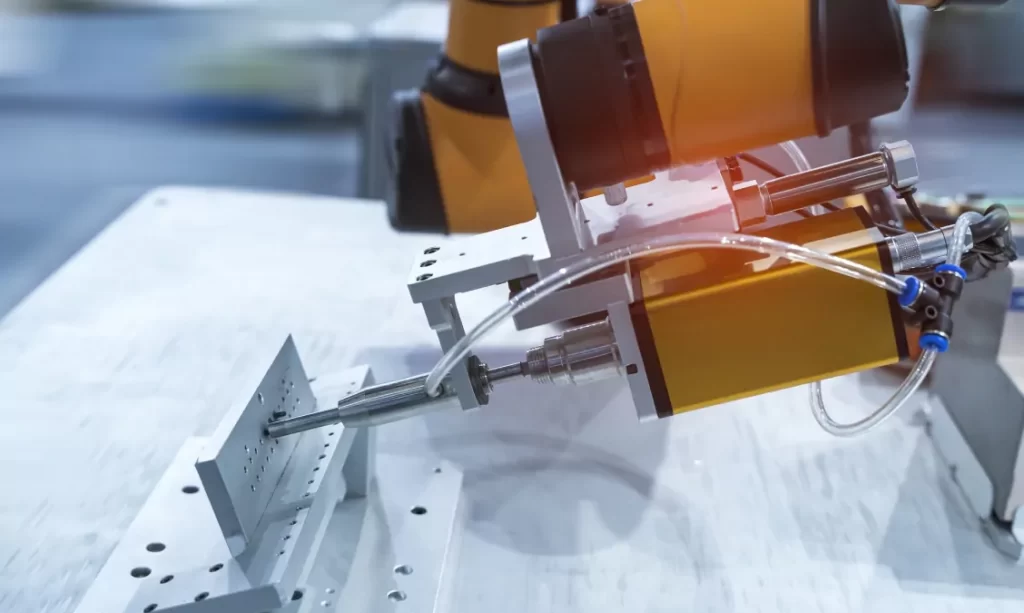

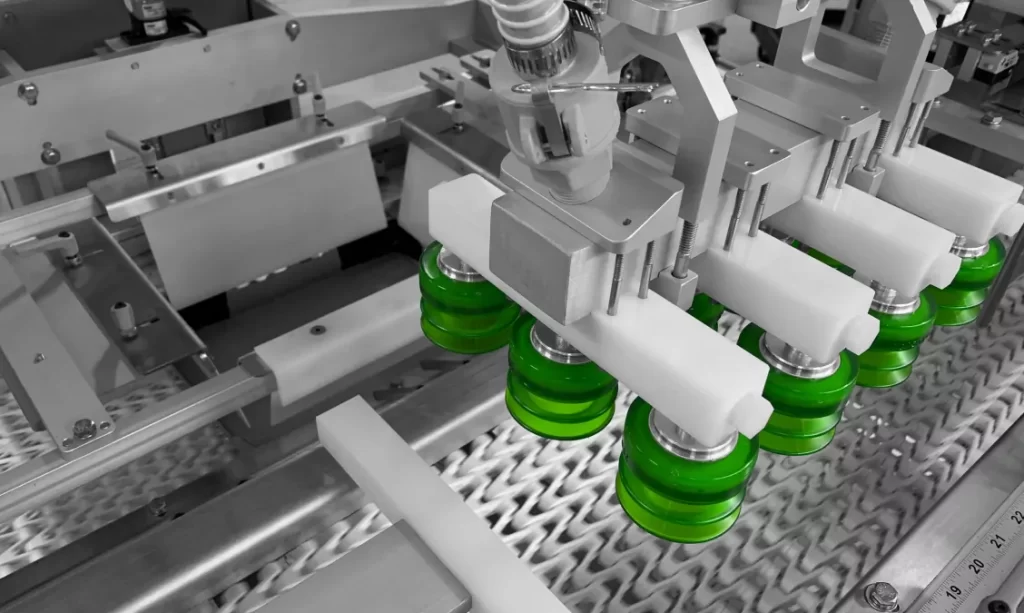

Many robots — particularly those used in manufacturing — have similar structures when it comes to parts like the arm and shoulder, but the end effector is what makes the robot unique and allows it to perform its chosen function. An end effector or end of arm tooling (EOAT) often requires several complex and intricate components that work together to allow the robot to grip, pick, cut, or do whatever it is tasked with doing.

As well as structural and task-specific parts, 3ERP is equipped to make casings, housings, tubing, and other important components for robotic assemblies. Made from plastic or metal, these important parts can be used to house structural elements, as well as mechanical and electronic components. Prototyping robotic housings can be achieved with low-cost processes 3D printing or urethane casting.

Robotics & Automation Part

Gallery

For the years we have gathered relevant experience that enables us to handle any aerospace projects. Here’s the gallery of aerospace prototypes and production parts for our worldwide clients.

Robotics & Automation Faqs

Is Orhong ISO Certified?

Yes, we are an ISO9001-2015 certified manufacturer. We manufacture parts to a high standard, no matter the project or the customer.

Can I Request A Sample?

For certain manufacturing processes like injection molding, we can provide a T1 sample for your parts, then further samples if required.

How Fast Can I Get My Parts?

We can fulfill orders quickly, but lead times depend on a few factors, such as the manufacturing process, order quantity, and part complexity. CNC machined parts can take as little as five days, 3D printed parts can take as little as three days, while moldings made via rapid tooling can take as little as 5–7 days.

I Want To Protect My IP — Are My Designs Secure?

Orhong values privacy and security with the utmost seriousness and will happily sign a non-disclosure agreement (NDA) at your request, giving you peace of mind about your intellectual property.

Put your parts

into production today

All information and uploads are secure and confidential.