Medical Prototyping

& Manufacturing

Get high-quality manufacturing services for your custom aerospace prototypes and production parts. Launch products faster, reduce risks, and streamline production processes with on-demand production at competitive prices.

- Production-grade products

- ISO 9001:2015 certified

- 24/7 engineering support

Medical Manufacturing Possibilities

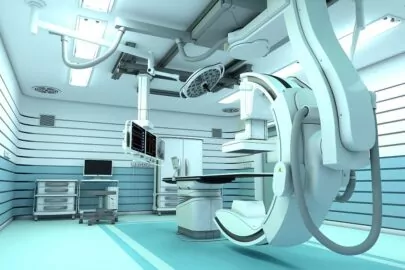

From fluid management systems to drug delivery devices to respiratory aids, many medical devices are composed of several constituent parts that often have highly complex designs. Getting these parts made — either as low-volume prototypes or in larger volumes — involves finding a manufacturing with the capacity and expertise to handle the project. Whether it’s a component for a new electronic device made via precision machining or a stainless steel cart made from sheet metal, 3ERP can fulfill your order.

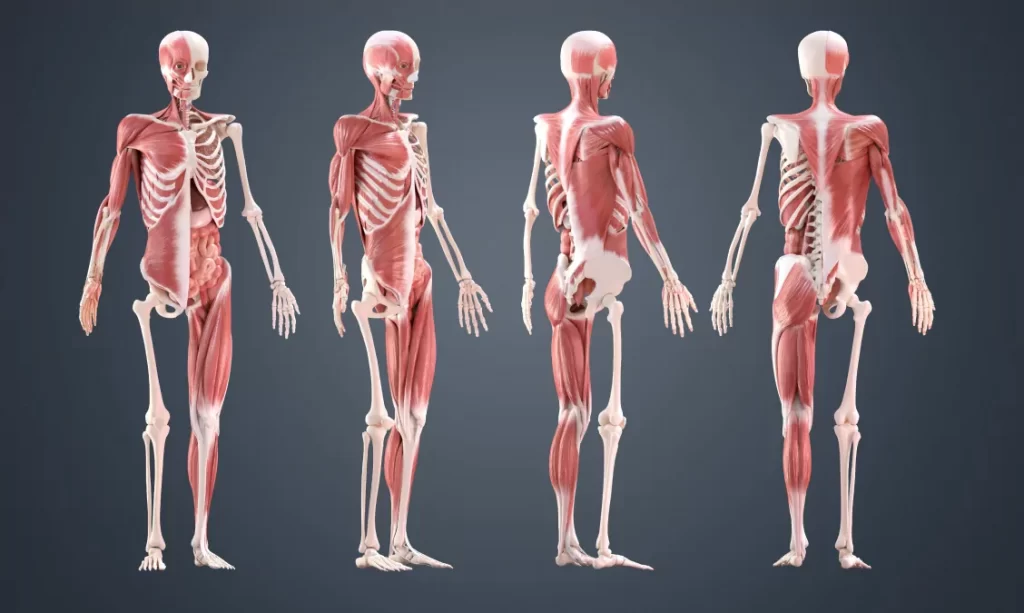

Anatomical models play several important roles in medicine. In educational contexts, they are used to train the next generation of doctors, nurses, and other medical professionals. Meanwhile in clinical and surgical environments they can be used to prepare for a procedure on a specific patient, providing a clear picture of an organ that needs operating on, for example. Digital manufacturing technologies like 3D printing have made it simple to fabricate such models from 3D designs.

Surgical instruments, handheld devices, and fixtures are just some of the important everyday medical parts we can fabricate using healthcare-friendly materials such as stainless steel, titanium, and PEEK with reliable manufacturing processes like CNC machining, molding, casting, and 3D printing. Whether you require prototypes or larger volumes of parts, we can fabricate complex designs or standard parts to your exact specifications.

Medical Part

Gallery

For the years we have gathered relevant experience that enables us to handle any aerospace projects. Here’s the gallery of aerospace prototypes and production parts for our worldwide clients.

Medical Faqs

Is Orhong ISO Certified?

Yes, we are an ISO9001-2015 certified manufacturer. We manufacture parts to a high standard, no matter the project or the customer.

Can I Request A Sample?

For certain manufacturing processes like injection molding, we can provide a T1 sample for your parts, then further samples if required.

How Fast Can I Get My Parts?

We can fulfill orders quickly, but lead times depend on a few factors, such as the manufacturing process, order quantity, and part complexity. CNC machined parts can take as little as five days, 3D printed parts can take as little as three days, while moldings made via rapid tooling can take as little as 5–7 days.

Can I Use My Parts In A Clinical Setting?

While we specialize in prototypes, we also offer medical-grade materials and a high-quality manufacturing service that may be suitable for your end-use parts. Contact us for more information.

Put your parts

into production today

All information and uploads are secure and confidential.