Competitive Reaction

Injection Molding

As a specialized reaction injection molding factory with various advanced machines, we are adept at producing PUR and PDCPD reaction injection molding with wall thickness from 3mm to 30mm.

- With over 10 years of abundant industry experience

- can handle the RIM of tricky materials such as PUR and PDCPD.

- Lead times from 3 business days

Take Advantage of Reaction Injection Molding

and greater convenience on your end.

Low Tooling Cost

RIM polymers can be injected into aluminum molds, which is more cost-effective than steel mold tooling.

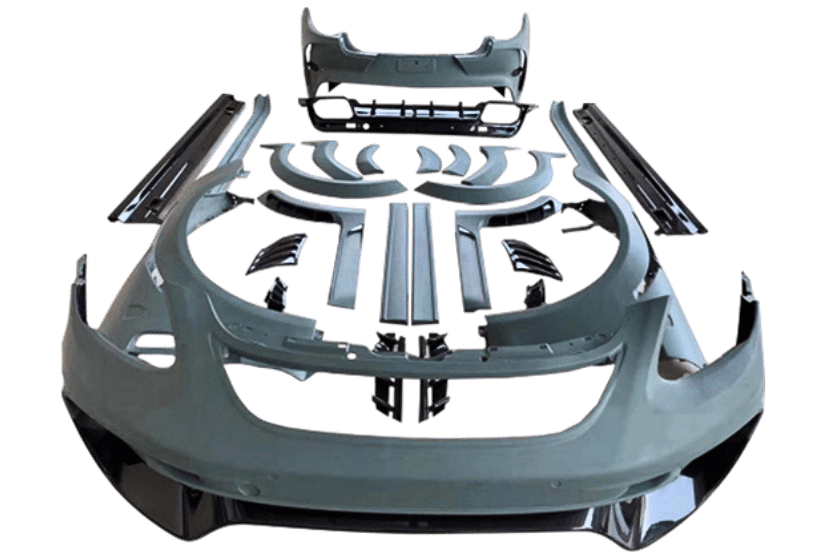

Flexible Part Size

Regarding the properties of the liquid polyurethane components, we can customize very large parts with RIM.

High Efficient Productivity

The low injection pressure of the RIM process allows for quick reaction injection molding at a lower cost.

High Precision

RIM can produce premium plastic products with structural integrity and high tolerances for optimal performance.

Complex Design

Our RIM provides greater structural integrity, tight tolerances, and varied ranges of wall thickness within the same part.

Beautiful Surface

RIM can create excellent surface features for aesthetically demanding applications.

Exceptional Reaction Injection Molding

With our high-end design capabilities, tricky material processing, and one-roof production,

we make products that match your desired preferences at lower costs.

Design Optimizing

With a thorough review of your CAD files or design drawings, we offer cost-effective design optimization to help save costs and improve product performance.

DFM & Mold Flow Analysis

Within our design for manufacturing review, we provide thorough analysis and suggest adjustments to improve the manufacturability and function of your plastic parts while keeping tooling and part prices down.

Advanced Facilities

Equipped with advanced reaction injection molding machines which can inject two sets of molds at the same time, we can save your time and ensure you efficient mass production at lower costs.

Competitive Achievable Materials

As fewer domestic manufacturers can support the reaction injection molding of PUR and PDCPD in China, we can handle requests to make competitive products for your market.

Complete Secondary Processing

Producing under one roof, we have the equipment to handle other processes to save time and reduce costs, from in-house assembly to durable surface treatment of parts.

Why Choose Us

As competitive figures and capabilities listed below, Orhong is your premier reaction injection manufacturer.

Low MOQ

We offer low value manufacturing with a minimum MOQ of 50.

Tolerance

We use advanced machines with a minimum tolerance of ± 0.2mm

Fast Lead Time

Fast reaction injection molding time can be as fast as 3 days.

Part Size

Maximum Part Size: 2000 x 1800 x 1500 mm; Minimum Part Size: 5 x 5 x 5 mm

Achievable Materials

rom structural foams to elastomeric polymers and PDCPD

Wall thickness

The wall thickness we can manufacture ranges from 3mm-30mm

Put your parts

into production today

All information and uploads are secure and confidential.